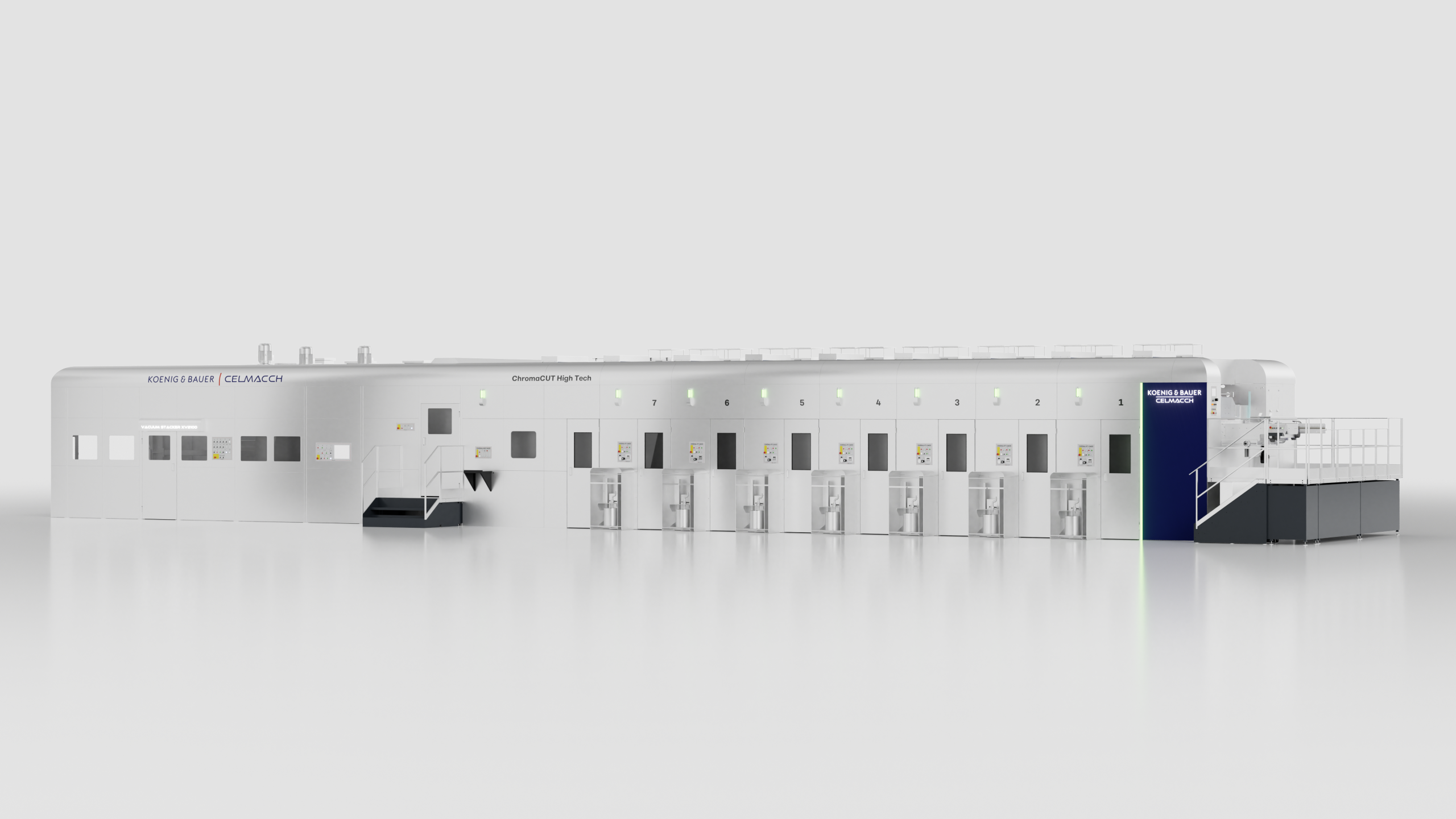

En noviembre de 2015, se instaló una nueva Chroma Print High Tech 2100 de cinco colores de última generación en línea con una nueva troqueladora plana en una de las mayores empresas papeleras de España. La impresora flexográfica destaca por su alta calidad de impresión y producción, así como por su durabilidad y tecnología de ahorro.

Celmacch ha desarrollado esta máquina con el objetivo de simplificar la tecnología y proporcionar una impresora flexográfica de alta calidad gráfica que sea intuitiva y fácil de usar para el operario.

La máquina es muy duradera; de hecho, Celmacch ha utilizado únicamente componentes suministrados por los principales fabricantes mundiales. La precisión de la impresión viene dada por una serie de dispositivos de alta tecnología, que Celmacch ha ido mejorando constantemente en los últimos años. En particular, utiliza el nuevo sistema de transporte por vacío, mejorado mediante el uso de alta fricción con una cubierta especial apta para altas temperaturas que ha sido desarrollada para ser duradera. Estos innovadores sistemas de transporte ofrecen la máxima precisión y un registro perfecto.

Para mejorar el registro, la Chroma Print está equipada con una innovadora cámara que corrige la posición del borde delantero. Un nuevo sistema de control de calidad ayuda a reducir los residuos y proporciona una producción con cero defectos.

Esta máquina está equipada con un nuevo sistema de inspección para controlar la calidad de impresión que está completamente integrado con el sistema de expulsión de hojas capaz de inspeccionar toda la superficie. Este dispositivo comprueba todos los defectos relacionados con la impresión y el fondo, el registro, la falta de texto, las manchas de registro, el código de barras, las salpicaduras y las variaciones de color. La máquina está totalmente equipada con tecnología de vanguardia y un aspecto nuevo y moderno. Tanto interna como externamente, la máquina se ha revestido de acero inoxidable para ayudar al operario a mantenerla en perfecto y óptimo estado a largo plazo.