Celmacch adopts Tadam clichés, realized with Kodak Flexcel NX Wide-C by Kodak for direct printing on corrugated board

The manufacturers of corrugated packaging today are increasingly demanding, they are seeking continuous improvement of production and the highest print quality. These results have been achieved and the quality of flexo printing is moving ever closer to the offset, thanks to a mix of business skills and experiences: Kodak with its innovative system Flexcel NX Wide-C for clichés; Tadam, well-known company located in Maltignano (AP) with strong expertise in the production of polymers, and Celmacch Group, a company based in Desenzano del Garda (BS), historic brand in the production of high-quality machines for printing on corrugated cardboard. For flexographic printing Chroma Print High Tech 1700,

Celmacch Group has adopted Tadam clichés with Flexcel NX Wide System-C Kodak, solving many problems of corrugated printers, such as ink coverage, absorption, washboard effect of corrugated cardboard visible after printing. So you can ensure a wider tonal range, screening with higher screen rulings, more efficient ink transfer and a high level of print quality even on low-quality cardboard.

TECHNOLOGY BY CELMACCH

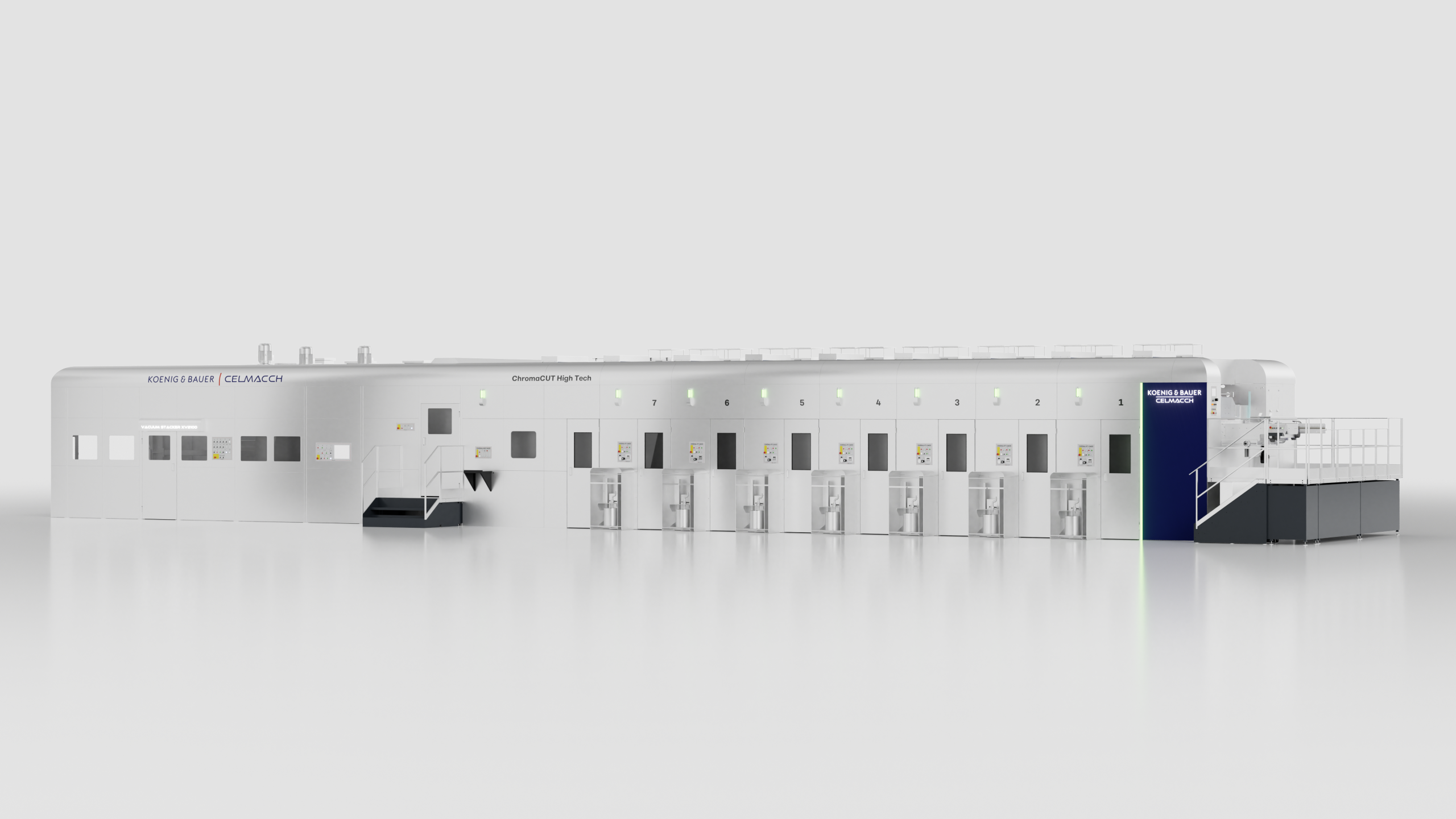

To evaluate what are the quality standards that can be reached by the latest technological solutions used for flexographic printing, Celmacch has recently produced and tested at its headquarters a Chroma Print High Tech 1700 line, equipped with the latest technology available. “The machine Chroma Print High Tech is our top-of-the-range machine”, explains Luca Celotti, Sales & Marketing Manager at Celmacch, “a flexographic printing machine (post print) with direct-drive, with technical devices to get the highest standards regarding precision and print definition”. It is in fact the last high-definition version of Chroma Print series, a modular printing machine, which can be composed of 2 to 7 printing units, depending on the various needs.

Thanks to the latest innovative technologies, such as clichés changing with machine in production, automatic change of anilox rolls, direct-drive technology and vacuum transport system (direct drive), you will reach the highest print quality, efficiency and maximum productivity, primary objectives for many companies. The machine is available in the off-line versions (with no-stop automatic stacker) and in-line (with the vacuum transfer), suitable for every model of automatic flat die cutter.

PRINTS MORE UNIFORM AND BETTER COLOR PERCEPTION

Tadam, a company specializing in the production of high-quality polymers, is the first company in Italy that is using the innovative system Kodak Flexcel NX Wide-C, which uses Flexcel NXC plates, in the corrugated cardboard sector, that allow you to print in flexo with offset quality.

Luca Celotti illustrates the features of the Kodak system that convinced him to choose Tadam as a partner: “The printers that use plates made with this system are guaranteed to have in print an optimum ink flow and a uniform coverage in solids, because the densities are compatible with offset. Besides, you can get the full chromatic scale from 1% to 100% as in the offset system. These advantages are achieved thanks to the particular engraving technology: in fact, while in the production of traditional digital flexo plates the oxygen inhibition during the UV exposure determines the round shape of the profile dot, especially in the highlights areas, the Flexcel NXC plate removes all oxygen during UV exposure, producing flat top dots with a solid basis and broad shoulders”.