Invest in Celmacch Chroma Evo to maintain high graphic growth.

High quality, affordable prices and durable products, these are for CELMACCH the starting points to provide its reliable and customized service.

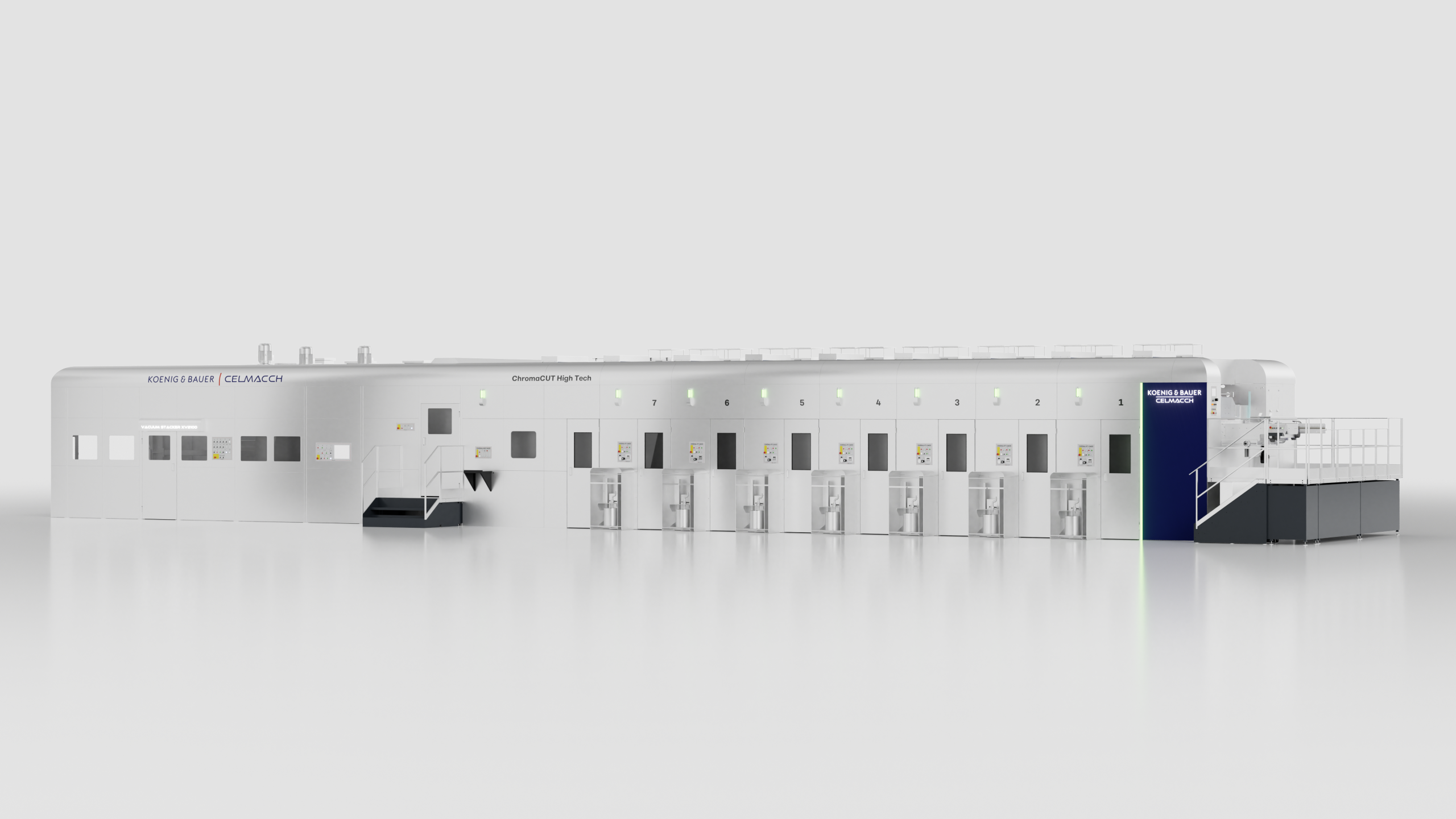

Celmacch has recently introduced two models of high definition flexo printers: Chroma High Tech II 1700 – 2100, the top of range printer, and Chroma EVO 1700 – 2100 with the aim to offer the best machine on the market in terms of quality, innovation and simple operator use.

Quality and Manufacturing according to top EU Standards guarantee the robustness and the excellent performances of these machines; only best components supplied by leading companies on the market, Siemens PROFINET technology and spare parts coming from European Countries are used to complete Celmacch printing machineries.

Chroma Evo is a flexographic machine embodying the perfect union of quality, superior engineering technology, and affordable price, qualities arising the interest of big multinational companies and crossing the needs of smaller firms, looking for an approachable investment, eager for enhance their competitiveness.

Chroma Print EVO has been designed and manufactured paying particular attention to the reduction of expenses related to spare purchase and technical assistance, without renouncing to advanced technology and high quality materials. The reached goal is to offer the highest value in a sophisticated but easy-to-use printing machine.

Chroma Print EVO is a HBL machine with fixed units designed to achieve the highest quality results and productivity. The direct drive technology and transport vacuum system by driven belts ensure great printing quality and high definition. The machine is available in two different formats 2100×1300 mm and 1700×1300 mm, both in “off-line” (with automatic stacker non-stop delivery) or “in-line” (with vacuum transfer) solution, it can be installed after any kind of automatic flat-bed die-cutter.

The innovative technical features characterizing this machine are:

- New direct drive feeder with belts in order to guarantee precision and maximum registration accuracy.

- Vacuum transport system with direct drive motors and extremely precise belts complete of adjustable suction system depending on the sheet size, with automatic control.

- Carbon fibre chambered doctor blades: developed to meet the highest quality standards. The doctor blades in carbon fibre provide several advantages such as anticorrosion, durability and easy and quick cleaning.

- Electrical drive: every cylinder is driven by independent motors and the synchronization is managed through SIEMENS SIMOTION drivers. The impression cylinder pressure is managed by an absolute linear transducer to ensure maximum reliability and accuracy.

- Adjustment of the printing length: printing length compensation device type XAPLC (automatic printing length control). It is very useful in case of printing with different distribution of masses. It allows to adjust lengthwise the printing size of each colour.

- Electronic features of the machine: Chroma’s Industrial communication is fully implemented in accordance with PROFINET standards, characterized by flexibility, reliability, robustness and increase of performance because of the high transmission speed.

- Sector dryers: Celmacch developed a new model of high efficient sector dryers which guarantee fast drying process thanks to the combination of infra-red rays and hot air. This system is divided in segments which can be activated.