Toscana Ondulati (Grupo Ds Smith) instaló una impresora flexográfica Chroma EVO en su planta de Perignano para alimentar su nueva troqueladora plana Bobst Mastercut 1.7 .

Toscana Ondulati forma parte de la multinacional DS Smith desde 1996, manteniendo su histórico nombre conocido en el mercado. La empresa cuenta con dos plantas de producción, una en Marlia (Lu) y otra construida en 2002 en Perignano; Toscana Ondulati es un centro de producción integrado dotado de los equipos más modernos necesarios para satisfacer cualquier necesidad de suministro de embalajes de cartón ondulado. Su planta onduladora produce el 90% de las planchas para satisfacer las necesidades de producción internas y el resto se fabrica para las demás plantas del grupo. DS Smith Perignano produce más de 100 millones de m2 de cartón y su facturación anual asciende a unos 45 millones de euros.

La actividad principal es la producción y transformación de microcanal para el sector alimentario, desde cajas de pizza para llevar hasta grandes envases de triple pared para diversos sectores industriales. En cuanto al sector alimentario, la planta de Perignano fue la primera de Italia en obtener la certificación BRC para garantizar el máximo nivel de seguridad alimentaria en toda la cadena de suministro. Todas las maquinarias se actualizan constantemente y, además de la onduladora, esta planta se beneficia de 8 líneas completas de transformación. La filosofía de Toscana Ondulati siempre ha sido producir todo en línea, debido a los enormes volúmenes producidos; esta forma de operar aporta obviamente ventajas en cuanto a calidad y eficiencia. En este caso, como ya ocurrió en otras instalaciones, la Chroma EVO de Celmacch completó la línea con una troqueladora suministrada e instalada por BOBST, que instaló esta Mastercut unos meses antes de la llegada de la impresora de Celmacch.

La nueva máquina flexográfica de Celmacch, una Chroma EVO 1700 de 5 colores, se adquirió para sustituir a una antigua con tecnología de los años 80, que ya no cumplía los requisitos de DS Smith en términos de calidad y seguridad. Se trata de la primera impresora flexográfica para DS Smith Toscana Ondulati, pero no para el grupo DS Smith, que ya ha elegido la tecnología de Celmacch para sus fábricas de toda Europa, precisamente por las referencias recogidas en nuestra empresa y por los excelentes resultados de impresión obtenidos durante varias pruebas y visitas a otras instalaciones de producción. La instalación y la fase de puesta en marcha fueron extremadamente rápidas, gracias también a la tecnología intuitiva y fácil de usar. La máquina ofrece un formato máximo de 1700 mm de anchura y 1300 mm de longitud de hoja.

Celmacch representa una vez más la opción ganadora para aquellas empresas que buscan una máquina flexográfica para configuración en línea con troqueladoras automáticas de última generación.

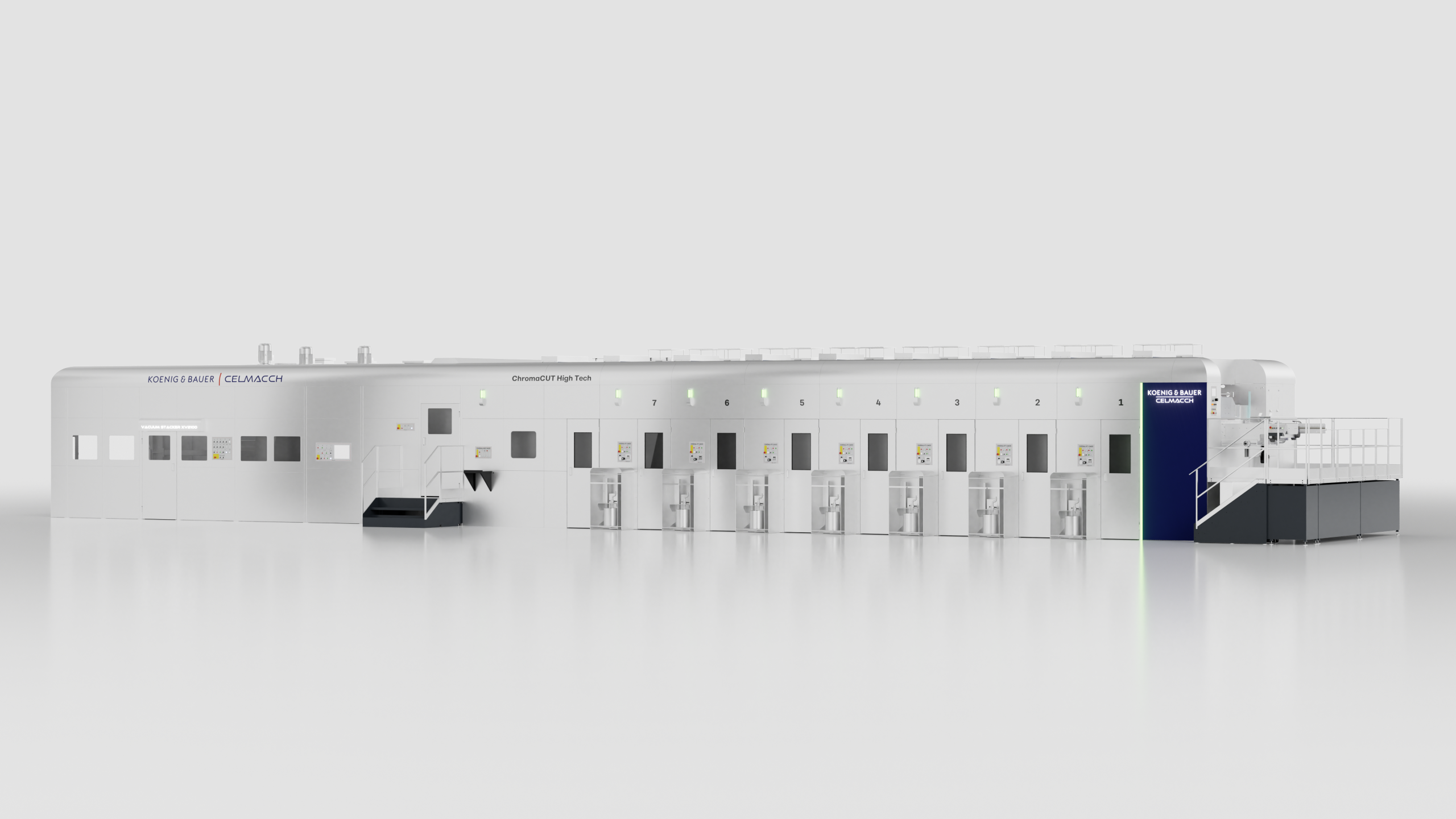

Celmacch ofrece una amplia gama de soluciones de impresión, en línea o fuera de línea, y troqueladoras rotativas: Chroma High Tech es el modelo de gama alta, Chroma EVO es el intermedio y Chroma Compact es la versión de entrada. La máquina elegida por Toscana Ondulati consta de un alimentador Siemens de accionamiento directo de última generación con correas de alta precisión. El transporte de la hoja está garantizado por una tecnología de vacío específicamente diseñada para asegurar la máxima adherencia y precisión de impresión, con el fin de obtener una tolerancia de registro de ± 0,2 mm entre los distintos colores. Gracias a la configuración HBL, el operador se beneficia de una ergonomía perfecta para realizar todas las operaciones de cambio de trabajo con la máxima eficacia y seguridad. Se ha prestado la máxima atención a todas las tecnologías que permiten un cambio de trabajo rápido: el cilindro de impresión está equipado con un sistema de fijación Matthews con sistema de tensado neumático. El sistema de entintado está equipado con un sistema de rasqueta con cámara de carbono, también desarrollado por Celmacch, una bomba peristáltica para la inyección de tinta y una bomba neumática de retorno. La máquina también cuenta con un nuevo sistema desarrollado por Celmacch para la limpieza diaria del anilox, consistente en una barra equipada con boquillas de alta presión, que garantiza la limpieza periódica y homogénea del anilox, con el fin de mejorar y prevenir los problemas de mantenimiento deficiente de los rodillos anilox. Chroma EVO, gracias a la transferencia por vacío, garantiza un funcionamiento perfecto en línea con troqueladoras de cualquier fabricantecomo, en este caso, una nueva Bobst Mastercut 1.7.