Celmacch instala otro Celmacch Chroma Print High Tech 2100X1300 en línea con una troqueladora automática Mastercut 2.1* producida y vendida por Bobst. Esta Chroma Print está equipada con un alimentador Alliance Pre.

WOK es una de las pocas empresas privadas de Polonia que sigue siendo propiedad de sus fundadores, especializada en la producción de cartón ondulado y envases de cartón ondulado. Se fundó en 1991 en Brodnica por iniciativa de Stefania y Stanislaw Wisniewski en respuesta a las necesidades del mercado. «Como director de la fábrica de dulces Vobro me enfrenté al problema de los suministros de envases para nuestros productos -recuerda Stanislaw Wisniewski, presidente de la empresa WOK-. – Con el consentimiento del propietario, mi esposa Stefania se encargó de adquirir cartón ondulado y yo mismo construí la primera troqueladora para envases. El plegado y el encolado se hacían manualmente. Mi mujer no tardó en conseguir otro cliente, una fábrica de nata local, y pronto resultó que el número de pedidos superaba nuestra capacidad de producción. Decidí dejar Vobro y centrarme en el negocio familiar. En 1996 construimos la primera onduladora eléctrica basándonos en la documentación de una máquina que funcionaba en la fábrica de papel de Bydgoszcz y empezamos a dar servicio a los fabricantes locales de muebles, para los que producíamos embalajes sencillos, no impresos, pero que -debido al tamaño de los productos- requerían una gran cantidad de cartón ondulado. En 2000 construimos una onduladora de vapor sencilla pero más profesional».

En 2003, se inició la construcción de un nuevo edificio compuesto por un moderno espacio de oficinas y una gran nave de producción y almacén que, ampliada gradualmente, permitió la expansión en el mercado polaco. En la actualidad, la superficie total de ambas plantas es de unos 30.000 m2 y WOK emplea a cerca de 400 personas. La empresa trabaja en régimen de tres turnos, 5 días a la semana y, si es necesario, también los fines de semana.

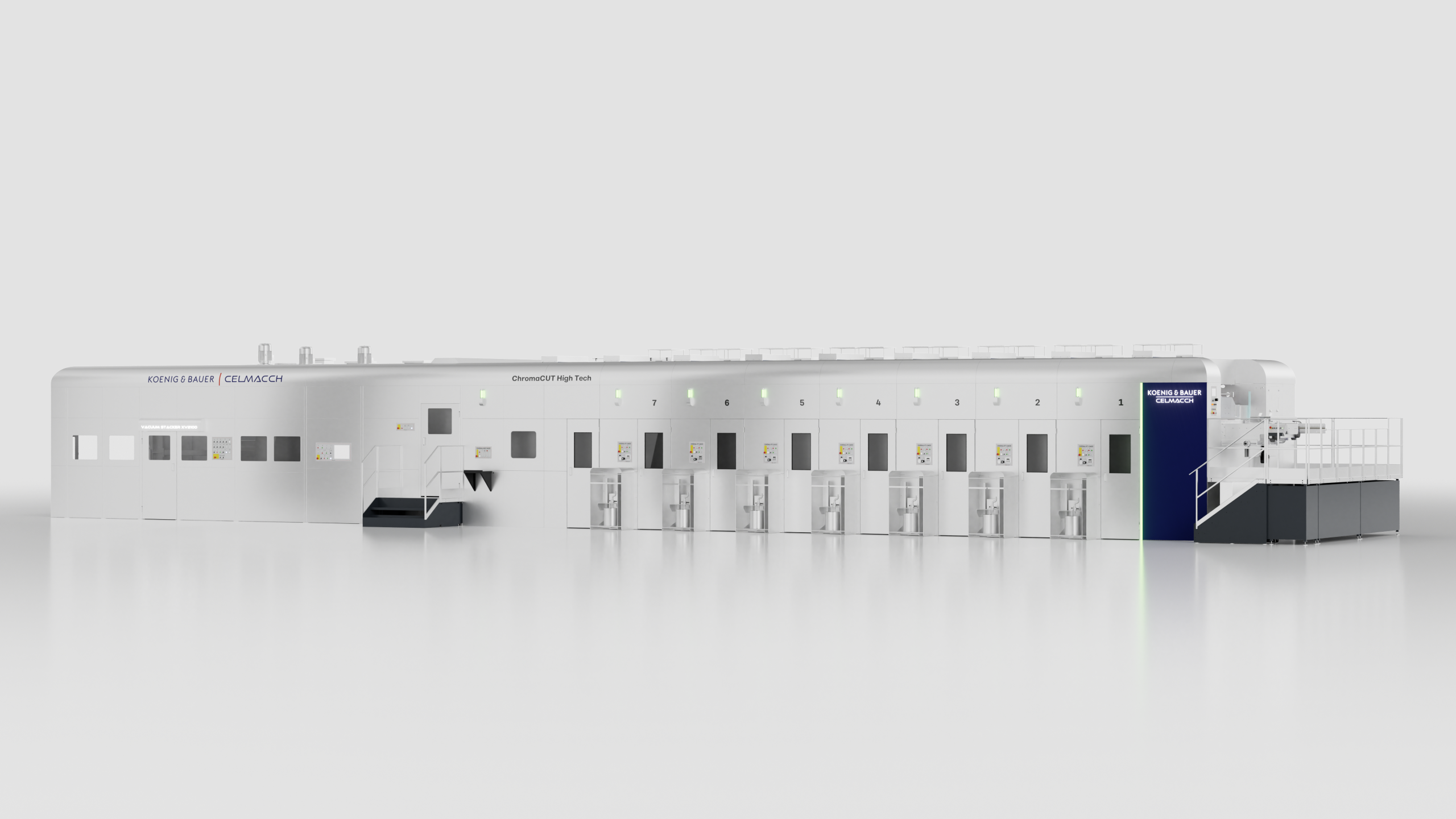

Wok optó por una impresora Chroma Print HT totalmente servoaccionada, equipada con alimentador motorizado de accionamiento directo, 3 colores y transferencia por vacío para la conexión a la troqueladora automática. Gracias a la automatización ofrecida por Celmacch, con Chroma Print HT la plancha de impresión puede cambiarse durante la producción y la velocidad mecánica es de hasta 10.000 hojas/hora. Con el nuevo sistema de lavado automático y la última generación de rasquetas con cámara de fibra de carbono, el lavado es muy rápido y eficaz. La instalación y la puesta en marcha de la Chroma Print se realizaron con gran rapidez, lo que permitió a WOK iniciar rápidamente la producción.

Wok ha elegido a Celmacch como socio para la impresión flexográfica de alta definición, comprando a sabiendas una de las impresoras flexográficas más avanzadas del mercado, que proporciona el mejor rendimiento y una tecnología fácil de usar que permite reducir los costes de mantenimiento, basándose en piezas comerciales y eliminando las piezas dedicadas que complican y encarecen el mantenimiento.

«Las máquinas de la serie Celmacch High Tech gozan de muy buena reputación en el mercado; sus usuarios no son sólo empresas privadas como la nuestra, sino también empresas mundiales de envasado, lo que fue una recomendación importante para nosotros -explica el presidente de WOK-. – La relación calidad/precio también fue crucial. La impresora flexográfica Celmacch formó parte de la inversión – su núcleo es la troqueladora Mastercut de Bobst que integramos con la máquina de impresión y el prealimentador fabricados por Alliance. La velocidad de 7.000 hojas por hora viene determinada por la capacidad de troquelado. La propia máquina puede imprimir con un tamaño máximo de hoja de 2100 x 1300 mm a una velocidad máxima de 10 000 hojas/hora. Estamos muy satisfechos con la calidad de impresión que ofrece la máquina Celmacch que hemos adquirido y, aunque hemos optado por una máquina de 3 colores debido a las limitaciones de espacio, ya estamos considerando la posibilidad de invertir en unidades de impresión adicionales o de adquirir una nueva máquina de 6 colores.»

La nueva línea permitirá a WOK adquirir pedidos de envases premium que requieren la máxima calidad de impresión gracias a la tecnología flexo HD que ofrece la nueva máquina de impresión. «Estamos especializados en envases para el mercado de masas, que se rige principalmente por el precio -explica Stanislaw Wisniewski-. – Sin embargo, cada vez más clientes están dispuestos a pagar más por una mayor calidad para destacar en el lineal, especialmente con envases listos para la venta, por lo que sin duda seguiremos invirtiendo para conseguir una calidad Full HD. Somos conscientes de que tres colores no bastan».

Gracias a la experiencia adquirida a lo largo de los años en el mercado del embalaje de cartón con impresión flexográfica, Celmacch conoce bien las necesidades de los clientes y de quienes trabajan en el sector y, partiendo de un análisis en profundidad de las necesidades, ofrece las soluciones más eficaces y de alta tecnología.

(*) «Bobst» y “Mastecut 2.1” son marcas registradas propiedad de Bobst SA y/o sus filiales. Celmacch no es el productor de la máquina Bobst y en aras de la claridad Celmacch desea aclarar que no existe ningún vínculo comercial y/o técnico entre Bobst y Celmacch.