Founded in 1928, Allard Emballages is one of the French leading companies in the corrugated market, specialized in the production of corrugated board paper and packaging for the food and industrial sectors.

Allard developed Europe’s largest combined offer, with solutions for agriculture, logistics and e-commerce, as well as for the end consumer, from transport crates to individual packaging, including heat-sealed trays for fresh foods, jars, and cups for the foodservice sector, as well as promotional displays.

In 2021 it became part of the Hinojosa Group, one of the largest family-owned industrial groups on the Iberian Peninsula, founded in 1947. With over 70 years’ experience and its multiple locations – 19 plants, 2.500 employees – throughout Spain, France and Portugal, Hinojosa Group is a leading manufacturer of corrugated cardboard.

The Group has achieved significant growth in recent years. Innovation, specialization, and close relationships with customers are the pillars on which this growth is based.

Last January 2024, Allard Emballages Brive, part of Hinojosa Group, and Koenig & Bauer Celmacch signed a new agreement for a new ChromaCUT High Tech 2800, 5 colors. This is not the first cooperation between Koenig & Bauer Celmacch and Hinojosa Group. In fact, three Celmacch flexographic printers Chroma High Tech are already present at the Hinojosa factories: the first one was installed in 2014 in Cipasi, the second one in 2017 in Envases Rambleños close to Córdoba, and the third one at the Xàtiva’s headquarters between the end of 2017 and January 2018.

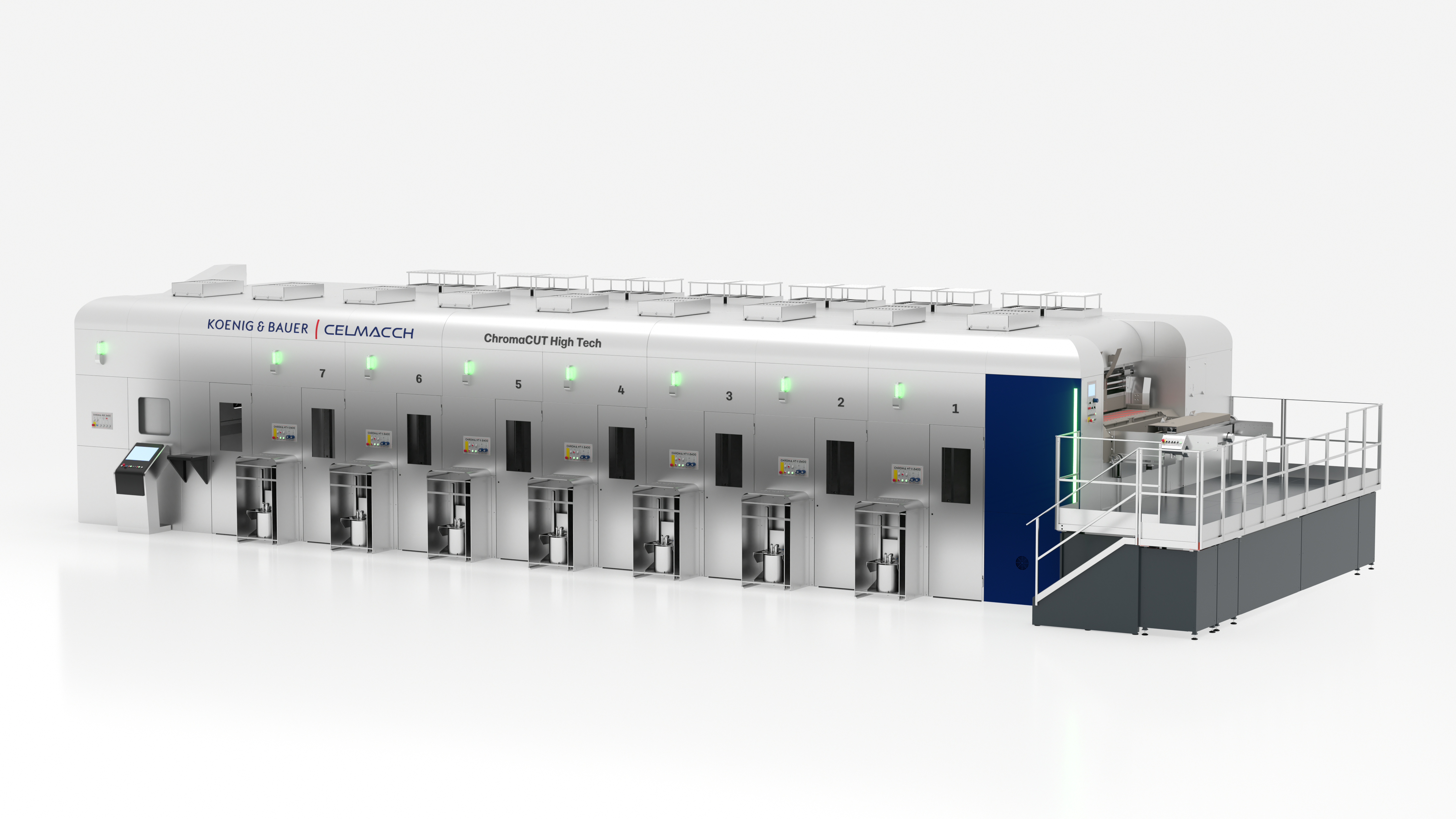

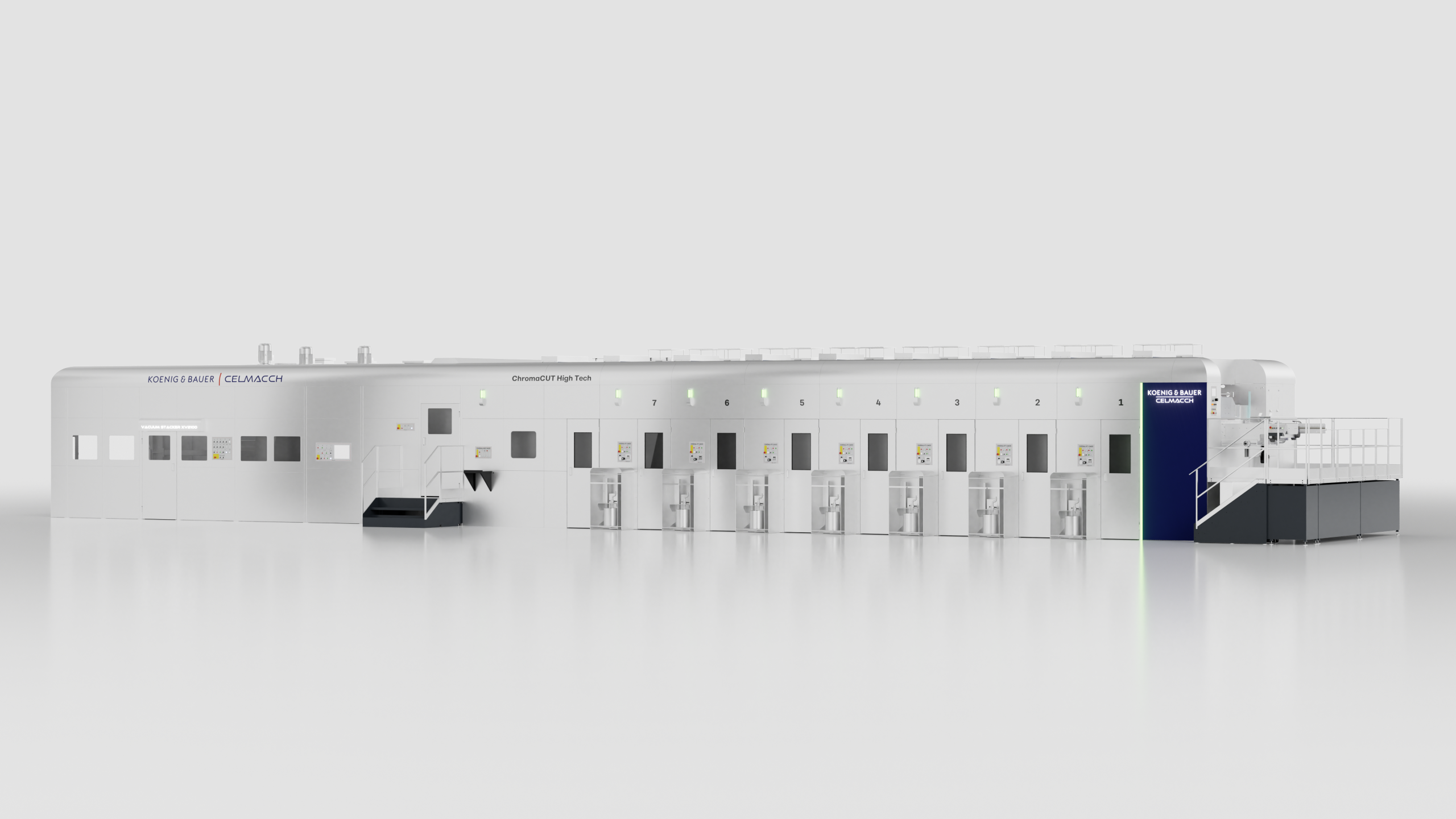

Allard Emballages placed an order with Koenig & Bauer Celmacch for the latest-generation ChromaCUT High Tech, fully driven by direct motors. With its higher degree of automation and considerably shorter makeready times, a working width of 2,800 mm, and a production speed up to 10.000 sheets per hour, the machine chosen by the French Company is extremely powerful. The technical specifications of the ChromaCUT HT are oriented towards the most demanding claims of Allard Emballages.

The ChromaCUT 2800 will be equipped with 1 feeding unit, 5 colors with vacuum transport sections, 1 rotary die cutter, 1 vacuum bundle stripping stacker and 1 motorized modular belt conveyor to be placed after the stacker and before the breaker. The new line will be delivered at the end of Summer 2024 and installed at the Brive-la-Gaillarde plant, in France.

The high board line and the open machine architecture allow the operator to set up the next job while the machine is running. It is equipped with all the features that ensure excellent printing quality and die cutting results. A motorized lifting device enables rolls changeover in approx. 3 minutes, in order to select the right anilox for each individual work.

The die-cutting accuracy is surprising. ChromaCUT was developed according to the highest European quality standards. All mechanical parts are manufactured in Italy, electronic components and direct drive motors are Siemens branded. The assembly of the whole machine takes place in Italy in Koenig & Bauer Celmacch’s factory in Desenzano del Garda to ensure the highest level of reliability over the long term. Luca Celotti, CEO and owner of Koenig & Bauer Celmacch, explains

“Chroma CUT is a combination of high print quality and a perfect rotary die cutter. It is not only a high-productivity rotary die cutter, but it also provides high-definition printing for highest quality results”. Mr. Celotti continues, “Innovation, continuous investment in the latest technological solutions, exclusive use of finest-quality components, durability, strength, reliability, and maximum performance in the long term, are the key success factors of our ChromaCUT rotary die-cutter.”