Europac has planned a multi million investment for its site in Dueñas, one of the main factories of the group in Spain, with both a paper mill and plant for converting corrugated board. This plant will strengthen its position as a leader in processing recycled white and coated paper of high-added value and the high-definition flexographic printing will play a very important role in this. The production site aims to improve its ability to produce high-quality printing and increase production capacity by 32%. Dueñas already has an excellent reputation when it comes to digital printing since it began collaborating with Hewlett Packard over a year ago.

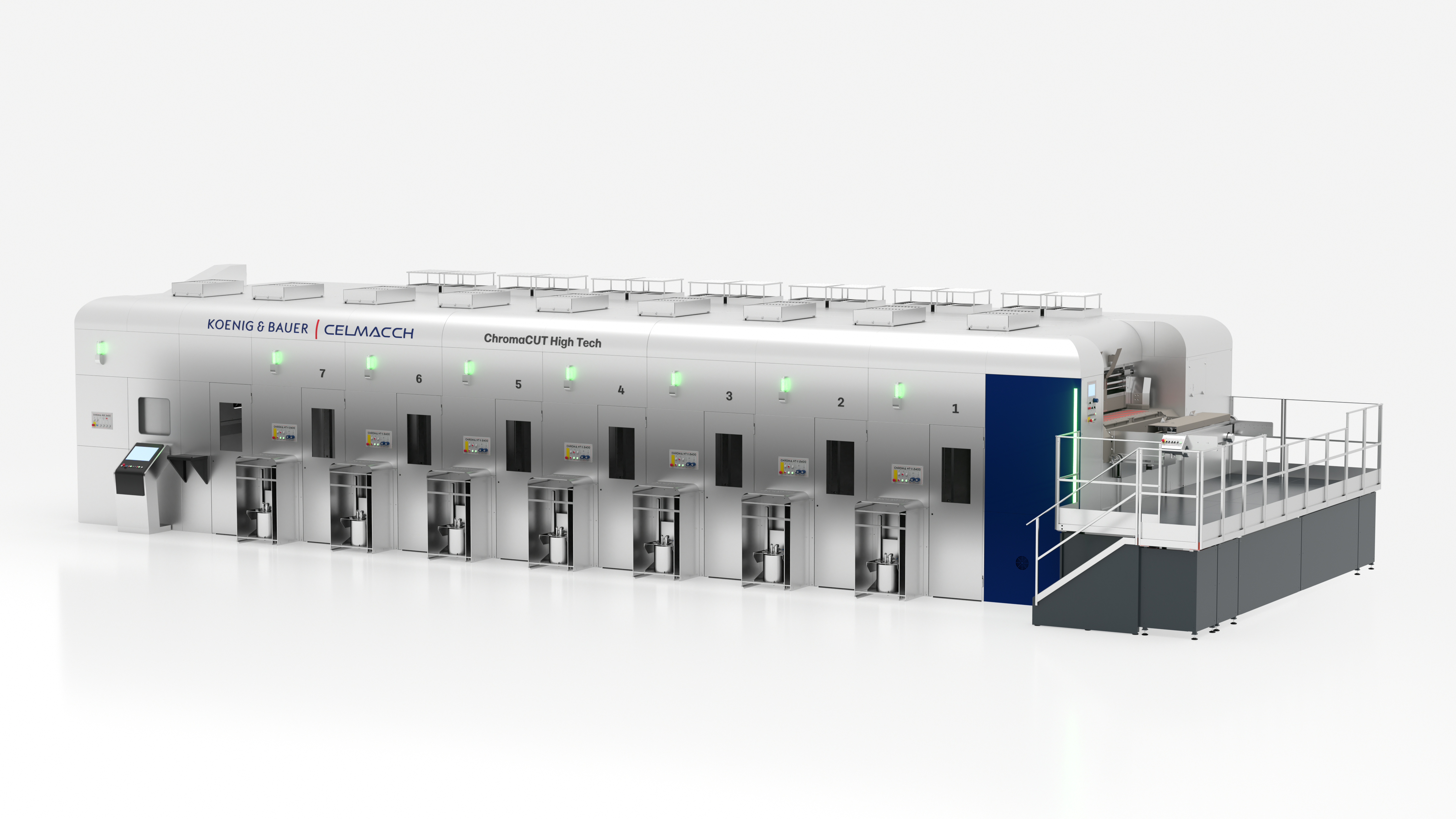

In April 2017, Celmacch installed a Chroma High Tech 1700 printer HBL, equipped with 6 colours and various optional features to provide the highest levels of high-definition printing and productivity. The lead edge feeder with wheels guarantees high performance and precision thanks to the Siemens servo motor. The machine is equipped with carbon chambered doctor blade and automatic wash-up system controlled by a PLC in each printing unit. The Celmacch machine also benefits from the advantages of servo drives since each shaft is powered by an independent Siemens motor. The print length compensation device enables the operator to easily and quickly adjust the print length on individual print units to compensate for any stretching.

The machine allows to prepare the next job without interrupting production thanks to the HBL configuration and to the presetting technology.

In all 6 printing units the machine is equipped with a system for automatically changing the anilox rolls: up to 3 rolls can be installed in each unit in order to use a range of anilox rolls, starting from more standard anilox rolls for traditional jobs to anilox with higher line screens for printing coated paper with high standards of quality close to offset.

The anilox roll can be changed very quickly and this feature means that the customer can avoid lengthy down time and more efficiently choose the most appropriate anilox for each the job. The machine is equipped with infrared lamps on each printing unit, allowing Europac to consolidate its position in high-definition printing on coated paper. The machine is also equipped with a system that checks the register between the feeder and the first colour and a second device to control register checking between colours.